Blow molding, inozivikanwawo sehollow blow molding, inzira inokurumidza kugadzira mapurasitiki ekugadzirisa.Munguva yeHondo Yenyika Yechipiri, kuvhuvhuta maitiro kwakatanga kushandiswa kugadzira yakaderera density polyethylene vials.Mukupera kwema1950s, nekuzvarwa kwe-high-density polyethylene uye kugadzirwa kwemichina yekuputira inoputika, tekinoroji yekuumba yekuvhuvhuta yakashandiswa zvakanyanya.Huwandu hwemidziyo isina humbowo hunogona kusvika zviuru zvemarita, uye kumwe kugadzira kwatora kutonga kwekombuta.Mapurasitiki akakodzera kuvhuvhuta kuumbwa anosanganisira polyethylene, polyvinyl chloride, polypropylene, polyester, etc. Izvo zvinokonzeresa makomba midziyo inoshandiswa zvakanyanya semaindasitiri ekurongedza midziyo.Zvinoenderana neiyo parison yekugadzira nzira, blowing molding inogona kukamurwa kuita extrusion blow molding uye jekiseni kuvhuvhuta.Iwo achangobva kugadzirwa ari akawanda-layer blow molding uye stretch blow molding.

Jekiseni kutambanudza kuvhuvhuta kuumba

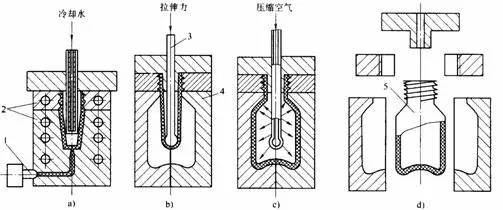

Parizvino, jekiseni rinotambanudza kuumba tekinoroji inonyanya kushandiswa kupfuura jekiseni kuvhuvhuta.Iyi bhobho yekuumba nzira zvakare jekiseni kuvhuvhuta kuumba, asi inongowedzera iyo axial tension, ichiita kuti kuvhuvhuta kuite nyore uye kuderedza kushandiswa kwesimba.Huwandu hwezvigadzirwa zvinogona kugadziriswa nekudhirowa majekiseni uye kuvhuvhuta yakakura kupfuura iyo nekufuridza jekiseni.Vhoriyamu yemudziyo inogona kupeperetswa ndeye 0.2-20L, uye maitiro ayo ekushanda ndeaya anotevera:

1. Nheyo yekugadzira jekiseni yakangofanana neyeyakajairika jekiseni molding.

2. Wobva watendeudzira parini kune yekudziya uye tembiricha yekudzora maitiro kuita kuti pariyo nyoro.

3. Tendeukira kuchiteshi chekudhonza uye uvhare mold.Tsvimbo yekusundidzira mukati mepakati inotambanudza parison padivi peiyo axial kutungamira, uku ichifuridza mweya kuita kuti parison iri padyo nemadziro ekuumbwa uye kutonhorera.

4. Kuendesa kune demoulding chiteshi kutora zvikamu

Cherechedza - kudhonza - kuvhuvhuta maitiro:

Jekiseni rekuumba jeri → chivako chekudziya → kuvhara, kudhirowa nekufuridza → kutonhora nekutora zvikamu

Schematic dhizaini yemuchina chimiro chejekiseni, kudhirowa uye kuvhuvhuta

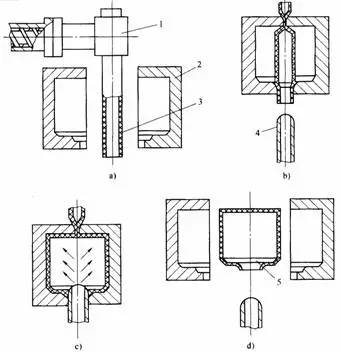

Extrusion blow molding

Extrusion blow molding ndeimwe yeanonyanya kushandiswa kuvhuvhuta nzira.Kugadziriswa kwayo kwakakura kwazvo, kubva kune zvigadzirwa zvidiki kusvika kumidziyo mikuru uye zvikamu zvemotokari, zvigadzirwa zvemakemikari emuchadenga, nezvimwewo. Maitiro ekugadzirisa anotevera:

1. Kutanga, nyungudusa uye sanganisa rubber, uye kunyunguduka kunopinda mumusoro wemashini kuti ive tubular parison.

2. Mushure mekunge jeri rasvika pakureba kwakafanotarwa, kuvhuvhuta mold kunovharwa uye jeri rinosungirirwa pakati pemahafu maviri emuumbi.

3. Furidzira mhepo, furidzira mhepo muchechi, furidzira pariso kuti iite pedyo negomba rekuumba.

4. Zvigadzirwa zvekutonhora

5. Vhura mold uye ubvise zvigadzirwa zvakaomeswa.

Extrusion blow molding process:

Kunyunguduka → extruding parison → kuvharika kwe mold uye kuvhuvhuta kuumba → kuvhura mold uye kutora chikamu

Schematic diagram ye extrusion blow molding musimboti

(1 - extruder head; 2 - blow mold; 3 - parison; 4 - compressed air blow pipe; 5 - epurasitiki zvikamu)

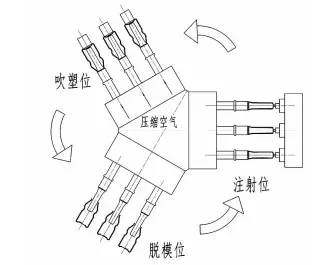

Jekiseni blow molding

Jekiseni blow molding inzira yekuumba iyo inosanganisa maitiro ekuumba jekiseni uye kuvhuvhuta.Parizvino, inonyanya kushandiswa kunwa mabhodhoro, mabhodhoro emishonga uye zvimwe zvikamu zvidiki zvechimiro zvine hunyoro hwekuputika.

1. Muchiteshi chekuumba jekiseni, mold embryo inotanga kubaiwa, uye nzira yekugadzira yakangofanana neyeyakajairika jekiseni.

2. Mushure mekuvhurwa kwejekiseni mold, iyo mandrel uye parison inotamira kune inoputika chiteshi.

3. Iyo mandrel inoisa parison pakati pemhepo inovhuvhuta mold uye inovhara mold.Zvadaro, mhepo yakamanikidzwa inoputirwa muchechi nepakati pemandrel, uye inobva yafuridzirwa kuti iite pedyo nemadziro ekuumbwa uye yakatonhodzwa.

4. Kana mold yakavhurwa, mandrel inotamirwa kune chiteshi chekudzikisa.Mushure mekunge chikamu chekuumba chinoputika chabviswa, mandrel inoendeswa kune jekiseni chiteshi kuti itenderedzwe.

Kushanda maitiro ejekiseni blower:

Kuvhuvhuta kuumba parison → jekiseni mold kuvhura kune firimu rinofuridza chiteshi → kuvharika kwe mold, kuvhuvhuta kuumba uye kutonhora → kutenderera kuenda kudhiza chiteshi kutora zvikamu → jeri

Schematic diagiramu yejekiseni blow molding musimboti

Zvakanakira uye kuipa kwejekiseni blow molding:

advantage

Chigadzirwa chacho chine simba rakawanda uye nepamusoro-soro.Iko hakuna kubatana pamudziyo uye hapana chikonzero chekugadzirisa.Kujeka uye kupedzwa kwepamusoro kwekurova kwakaumbwa zvikamu zvakanaka.Inonyanya kushandiswa kumidziyo yepurasitiki yakaoma uye midziyo yemuromo yakakura.

kushomeka

Mutengo wemidziyo yemuchina wakakwira zvakanyanya, uye kushandiswa kwesimba kwakakura.Kazhinji, midziyo midiki chete (isingasviki 500ml) inogona kuumbwa.Zvakaoma kuumba midziyo ine zvimiro zvakaoma uye elliptical zvigadzirwa.

Kunyangwe iri jekiseni kuvhuvhuta kuumba, jekiseni kudhonza kuvhuvhuta kuumba, extrusion dhonza blow blow molding, yakakamurwa kuita imwe-nguva kuumba uye kaviri kuumba maitiro.Iyo-imwe-nguva yekuumba maitiro ine yakakwira otomatiki, yakanyanya kurongeka kweparison clamping uye indexing system, uye yakakwirira yemidziyo mutengo.Kazhinji, vagadziri vazhinji vanoshandisa kaviri kuumba nzira, ndiko kuti, kuumba chivako chekutanga kuburikidza nejekiseni rekugadzira kana extrusion, vozoisa jeri mune mumwe muchina (jekiseni rinoputika muchina kana jekiseni rekudhonza blow machine) kuburitsa chigadzirwa chakapedzwa, nepamusoro. kugadzirwa zvakanaka.

Nguva yekutumira: Mar-22-2023