Iyo mold inowanzova nechikamu chemukati chete uye hapana punch.Iyo mold surface haidi kuomeswa.Iyo yekuvhuvhuta inotakurwa negomba idiki pane iyo yekuumbwa kwejekiseni, kazhinji 0.2 ~ 1.0MPG, uye mutengo wakaderera.

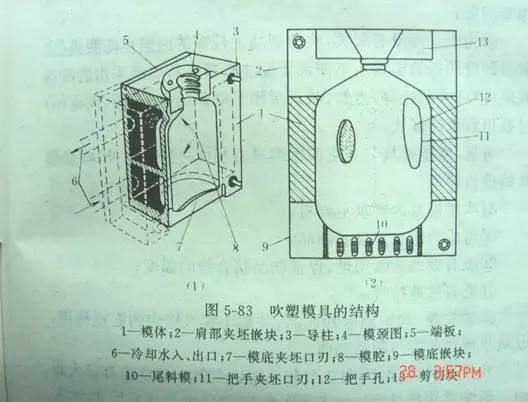

Blow mold structure diagram

Mold material

Kazhinji, aruminiyamu alloy inoshandiswa pakugadzira, uye beryllium mhangura kana copper base alloy inoshandiswawo kune corrosive rubber zvinhu zvakaita sePVC nePOM.Kune ma mold ane yakakwirira sevhisi zvinodiwa zvehupenyu, senge blow molding engineering mapurasitiki ABS, PC, POM, PS, PMMA, nezvimwewo, simbi isina tsvina inodiwa kuti ishandiswe kugadzira mold.

mold

Zvinhu zvakakosha zvekugadzira mold

Kuparadzana pamusoro

Kazhinji, inofanira kuiswa pa symmetry plane kuderedza kuvhuvhuta kuwedzera kuwedzera.Semuenzaniso, kune zvigadzirwa zve elliptical, nzvimbo yekuparadzanisa iri pane axis refu, uye kune giant zvigadzirwa, inopfuura nemutsetse wepakati.

Cavity pamusoro

PE zvinhu zvinofanirwa kuve zvakaomarara zvishoma, uye pamusoro pejecha rakanaka rinoita kuti ripere;Nekuvhuvhuta kwemamwe mapurasitiki (akadai seABS, PS, POM, PMMA, NYLON, nezvimwewo), mold mhango kazhinji haigone kuputirwa nejecha, uye iyo epositi inogona kugadzirwa panzvimbo inoparadzana yegomba, kana kubuda. gomba rinogona kuitwa pamhango yekuumbwa, uye dhayamita yegomba rekuburitsa pane general mold mhango φ 0.1~ φ 0.3, kureba 0.5 ~ 1.5mm.

Cavity size

Iyo shrinkage rate yemapurasitiki inofanirwa kutariswa mukugadzirwa kwegomba size.Kuti uwane ruzivo, ndapota tarisa kune akajairwa epurasitiki shrinkage mitengo.

Kucheka kumucheto uye tailing groove

Kazhinji, kuvhuvhuta kuumba mainjiniya mapurasitiki uye mapurasitiki akaomarara, kuchekwa kunofanirwa kugadzirwa nezvinhu zvine kusakara kwakanaka, senge beryllium mhangura, simbi isina tsvina, nezvimwe. Kune LDPE, EVA uye zvimwe zvinyoro zvigadzirwa zvepurasitiki, general aluminium alloy inogona kushandiswa. .

Kucheka kunofanira kusarudzwa nehukuru hunonzwisisika.Kana iri duku, inoderedza simba rejojo.Kana yakakurisa, haigone kuchekwa uye mupendero wekusungirira panzvimbo yekuparadzana wakakura.Nekudaro, giro remuswe rinovhurwa pazasi pekucheka kwekucheka, uye iyo tailing groove yakagadzirirwa kuve inosanganisirwa kona.Paunenge uchicheka, kunyunguduka kuduku kunogona kunyungudutswa mumubatanidzwa, nokudaro kuvandudza simba rekubatana.

Injection blow mold

Iyo yakagadzirwa yakasiyana neye extrusion blow molding.Musiyano mukuru ndewekuti jekiseni rinovhuvhuta mold haidi kucheka mupendero uye tailing groove.Iyo isina chinhu dhizaini yejekiseni inoputika chikamu yakakosha, iyo inobata zvakananga kunaka kwechigadzirwa chakapedzwa.

Injection mold - parison design misimboti

1. Kureba, dhayamita uye kureba ≤ 10/1

2. Kufuridza yekuwedzera reshiyo 3/1~4/1 (reshiyo yehukuru hwechigadzirwa kune saizi yeparson)

3. Wall ukobvu 2 ~ 5.0mm

4. Maererano nechimiro chechigadzirwa, rusvingo rwemadziro rwakakura apo chiyero chekuvhuvhuta chakakura, uye chakaonda apo chiyero chekuvhuvhuta chiri chiduku.

5. Pamidziyo ine ellipse ine ellipse ratio yakakura kupfuura 2/1, core rod ichagadzirwa se ellipse.Kune zvigadzirwa zve elliptical zvine ellipse ratio isingasviki 2/1, iyo yakatenderedza core rod inogona kugadzira ellipse mudziyo.

Kufuridza tsvimbo kugadzira

Chimiro chemhepo inovhuvhuta tsvimbo inotemerwa zvichienderana nechimiro che mold uye zvigadzirwa zvinodiwa.Kazhinji, iyo yekusarudza dhayamita yegomba yemhepo yekupinda tsvimbo ndeye:

L<1: aperture φ one point five

4> L>1: kuvhura φ nhanhatu pfungwa shanu

200>L>4: buri φ 12.5 (L: vhoriyamu, chikwata: rita)

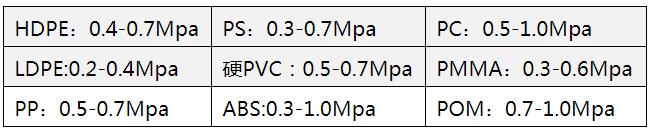

Air pressure ye common plastic blow molding

Nguva yekutumira: Mar-22-2023